Cool Guides

Rules for Posting Guides on Our Community

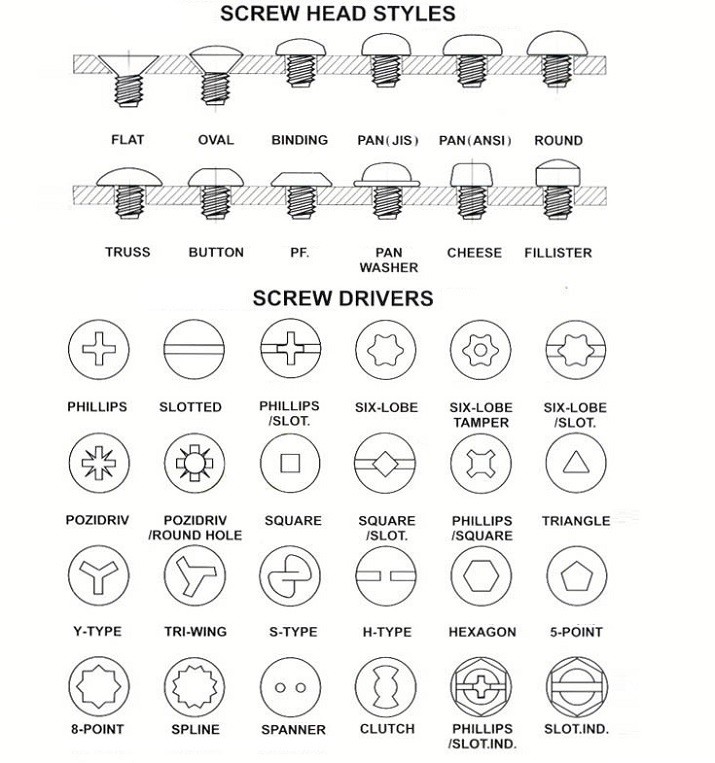

1. Defining a Guide Guides are comprehensive reference materials, how-tos, or comparison tables. A guide must be well-organized both in content and layout. Information should be easily accessible without unnecessary navigation. Guides can include flowcharts, step-by-step instructions, or visual references that compare different elements side by side.

2. Infographic Guidelines Infographics are permitted if they are educational and informative. They should aim to convey complex information visually and clearly. However, infographics that primarily serve as visual essays without structured guidance will be subject to removal.

3. Grey Area Moderators may use discretion when deciding to remove posts. If in doubt, message us or use downvotes for content you find inappropriate.

4. Source Attribution If you know the original source of a guide, share it in the comments to credit the creators.

5. Diverse Content To keep our community engaging, avoid saturating the feed with similar topics. Excessive posts on a single topic may be moderated to maintain diversity.

6. Verify in Comments Always check the comments for additional insights or corrections. Moderators rely on community expertise for accuracy.

Community Guidelines

-

Direct Image Links Only Only direct links to .png, .jpg, and .jpeg image formats are permitted.

-

Educational Infographics Only Infographics must aim to educate and inform with structured content. Purely narrative or non-informative infographics may be removed.

-

Serious Guides Only Nonserious or comedy-based guides will be removed.

-

No Harmful Content Guides promoting dangerous or harmful activities/materials will be removed. This includes content intended to cause harm to others.

By following these rules, we can maintain a diverse and informative community. If you have any questions or concerns, feel free to reach out to the moderators. Thank you for contributing responsibly!

view the rest of the comments

The problem you have with slotted screw heads is twofold.

You buy the cheapest and crappiest set of straight bladed drivers the dollar store sells. Manufactured by some poor Pakistani dude squatting in the dirt and wearing his safety squints and safety sandals as he bashes each one out with a hammer and scrap steel anvil.

You have no idea that those drivers are actually meant to be fitted to the slotted screw you are working with. Not that it matters, you won't take the time and effort to do so anyway.

A good set of straight blade screw drivers cost real money. They a forged and then the tips are hollow ground to get purchase in the slot to prevent cam out. Check the cost of a set of gunsmithing screwdrivers. And no one that actually has a set or two of those is afraid to modify the tips to correctly make the screwdriver, (or as the British so elegantly put it-- turnscrews back in the day), fit the slot.

While we have far better designs these days, they are complicated to make and require special tooling to manufacture. And a big advantage to the slotted screw is if you strip out one of those much fancier types, you can often just take a small flat file and pretty quickly cut a slot to try again. (looking at you Philips head).