3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: or !functionalprint@fedia.io

There are CAD communities available at: !cad@lemmy.world or !freecad@lemmy.ml

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe/ may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

view the rest of the comments

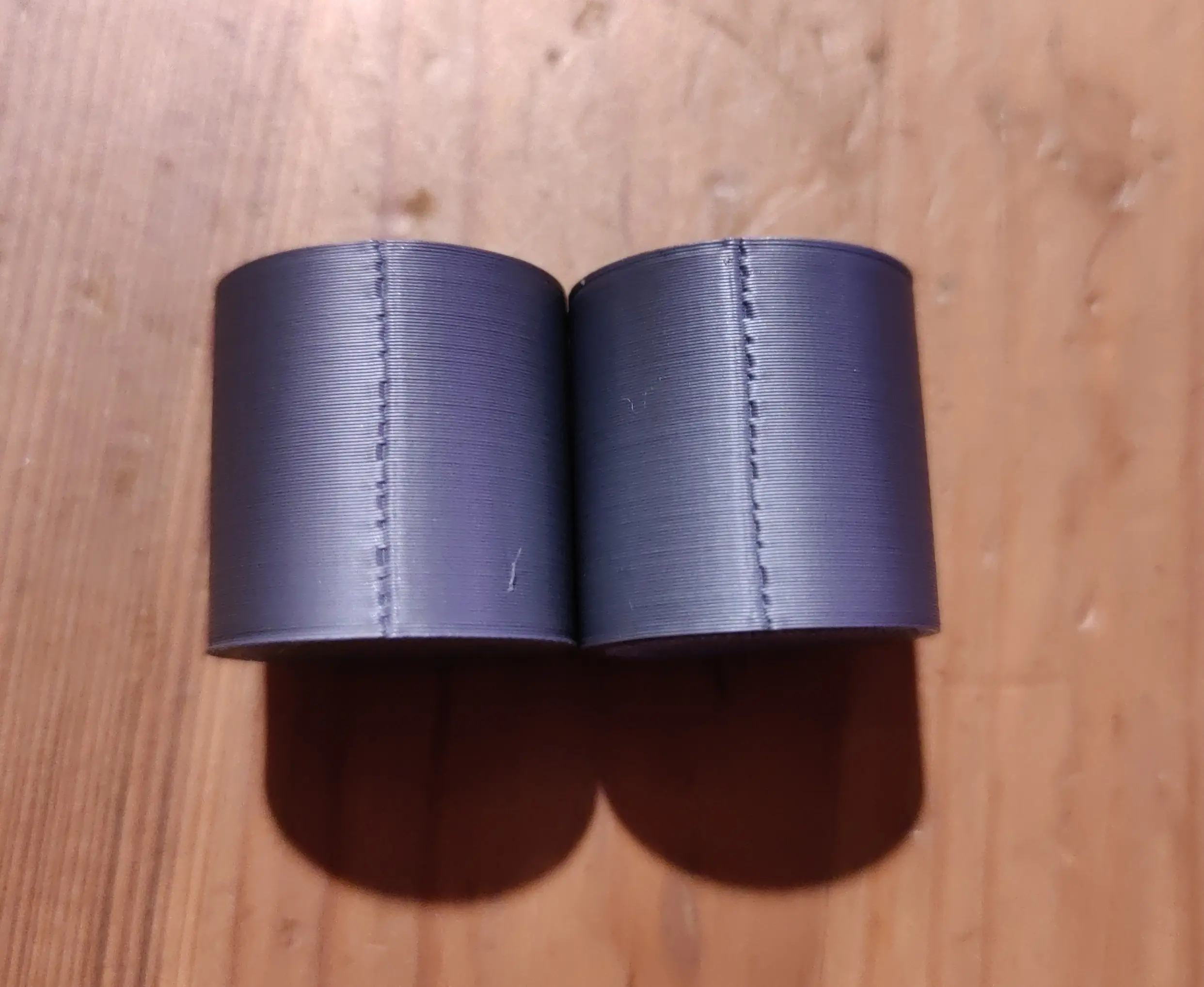

What printer do you use. This is a mechanical issue. It's something binding as the one x or y is traveling could be a bearing or the stepper motor it self. It prevents the arc from being fully formed even though the machine thinks it is key point you made is that randomized z seam leaves the same mess, but if notice it's not all the layers are cut short only some.

Take the belt off and move the axis by hand slow and easy do you feel anything that isn't smooth like silk? That would be it. Feel the stepper is the drive gear tight any slip ?? Any play in the shaft side?

Edit

Looking at the pictures again I'd bet that if you went taller and printed faster, it would be even worse because the bad part got hotter and more bound up more Alternatively printing faster might make it better because you have the inertia to push past the binding spot.

It's an anycubic kobra 2 running klipper.

Randomized seams leaves the same mess, but randomly distributed around the model and not aligned like in the picture. But each seam is equally bad everywhere on the model.

Speed doesn't seem to affect the issue, I've tried both 30mm/s and 100mm/s

I disassembled the X and Y axes yesterday to check the motion system, moving by hand seems as smooth as it's ever been, no slip that I could feel. I think one roller on the X axis is very slightly oval unfortunately, but moving the model to different locations have no effect on this, and rotating models so seams align differently on the axes doesn't change anything, so I don't think that's the source of the issue.

Can you post the g code ?

I'll post it later today