More auditing! The factory's been online long enough, I should have produced SOME Adaptive Control Units by now, but I haven't. Apparently, we're not actually making any Modular Frames.

Looks like Limestone isn't working? Both Steel Pipe and Concrete are dependent on Limestone. Although, so is Encased Industrial Beam...

Okay, so just half of Limestone wasn't running.

Also, found a spot where I forgot to connect a Conveyor Lift, to pass the overflow from the Encased Heavy Frame sushi belt, into the main AWESOME Sink line.

While that primes up, we can look at the Caterium Computers loop, which is definitely not working properly. Can't really tell from the screenshot, but this is where the leftovers on the sushi belt loop back and get re-injected to the front of the belt (if there's room). But somehow, we're not getting enough Quickwire.

Even though we're producing plenty.

I eventually realized I have a critical design flaw both here, in the Circuit Boards logistics, and in the Quickwire logisitcs.

Some background: there are basically 2 ways to handle load balancing and efficiency in Satisfactory (at least, in my mind): upstream throttling, or downstream backpressure.

Technically, there's a third: belt dividing with splitters and mergers, into specific ratios, but I almost never use that, cause once you get beyond Iron Plates, Iron Rods, and Wire, the ratios are infeasible to make perfect.

Upstream throttling is just down-clocking your production machines to exactly-match how much input your consumer machines require. Actually, for me, it most often means running the upstream machines at the highest speed I can, and clocking the downstream machines to match, but ultimately, the idea is that the upstream can't produce more than the downstream can consume, so everything runs at 100% efficiency.

Downstream backpressure is how I most-often balance a set of production machines that are feeding more than one set of consumer machines (E.G. Iron Ingot feeding both Iron Plate and Iron Rod). And really, it just involves the same thing as throttling: setting all the machine clocks so that the producers are making exactly as much as the consumers, and then just splitting the line. Splitters always divide resources in a 1:2 or 1:3 ratio, and since that's basically NEVER the desired split, you'll always end up supply too much resource to one of the downstream consumers, and not enough to the others. However, as long as you're only using basic splitters, it doesn't really matter. Because the clocks all match, eventually the belts for the consumers that are receiving too much will back up, and the excess will naturally flow over to the other consumers, until it all balances out. I.E. the consumers that are receiving too much of a resource will apply "backpressure" to force the exact split of resources you want.

So, the problem with the Circuit Board and Quickwire logistics I found is that I am splitting each of them to feed 2 separate production lines. However, each of those production lines is a sushi belt loop, which by my design DOES NOT PROPAGATE BACKPRESSURE. I specifically include a Smart Splitter with Overflow to an AWESOME Sink in each sushi loop, to make sure they don't jam, but that, by definition, is absorbing any backpressure. It's impossible for me to split the lines of Circuit Boards and Quickwire in the precise ratios I need. If there was only ONE consumer that did not provide backpressure, I could mitigate that by splitting with a Smart Splitter that prioritizes the one that does, but in this case, BOTH consumers are sushi loops, for both of these resources.

So, since I can't use backpressure to precisely divide up the Circuit Boards and Quickwire, I have to use throttling, I.E. instead of having one production line of Quickwire feeding 2 production lines that consume it, each consumer needs its own, independent production line that is throttled to its needs. Same for Circuit Boards.

You can see here some of the re-belting I had to do to run separate lines of Quickwire and Circuit Boards, where they were unified before.

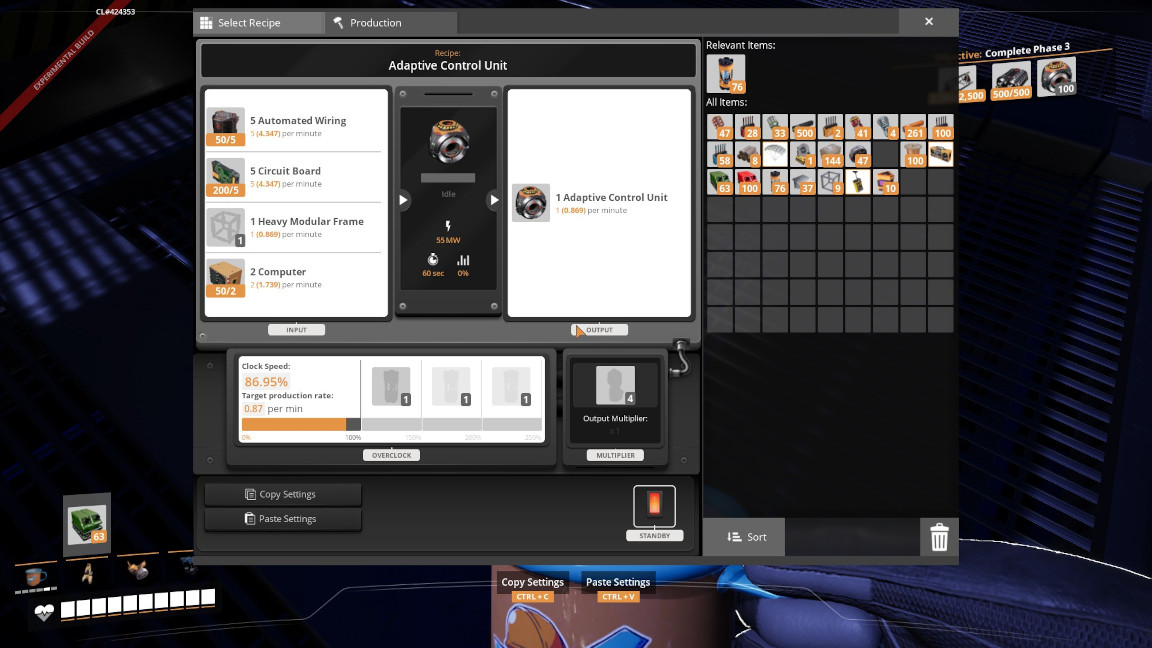

Ultimately, we are rewarded with production!