When I first started soldering my parents bought me a (probably < $10 at the time) hobby soldering iron. That iron took a beating and was replaced with another hobby iron then another. I ended up with a hobby iron that I absolutely loved. It had a powder blue handle, a solid barrel (not rolled sheet) and was flared where the handle met the barrel. I used that iron for many years. I am not sure where it went. It may be in a box of tools somewhere or it may be gone for good.

I'm not sure exactly when I got my Weller WESD51 soldering station. It will have been between 15 and 20 years ago. At around $150 it was an expensive upgrade for me. That original station still sits on my desk and up until a few weeks ago was the only station on my desk.

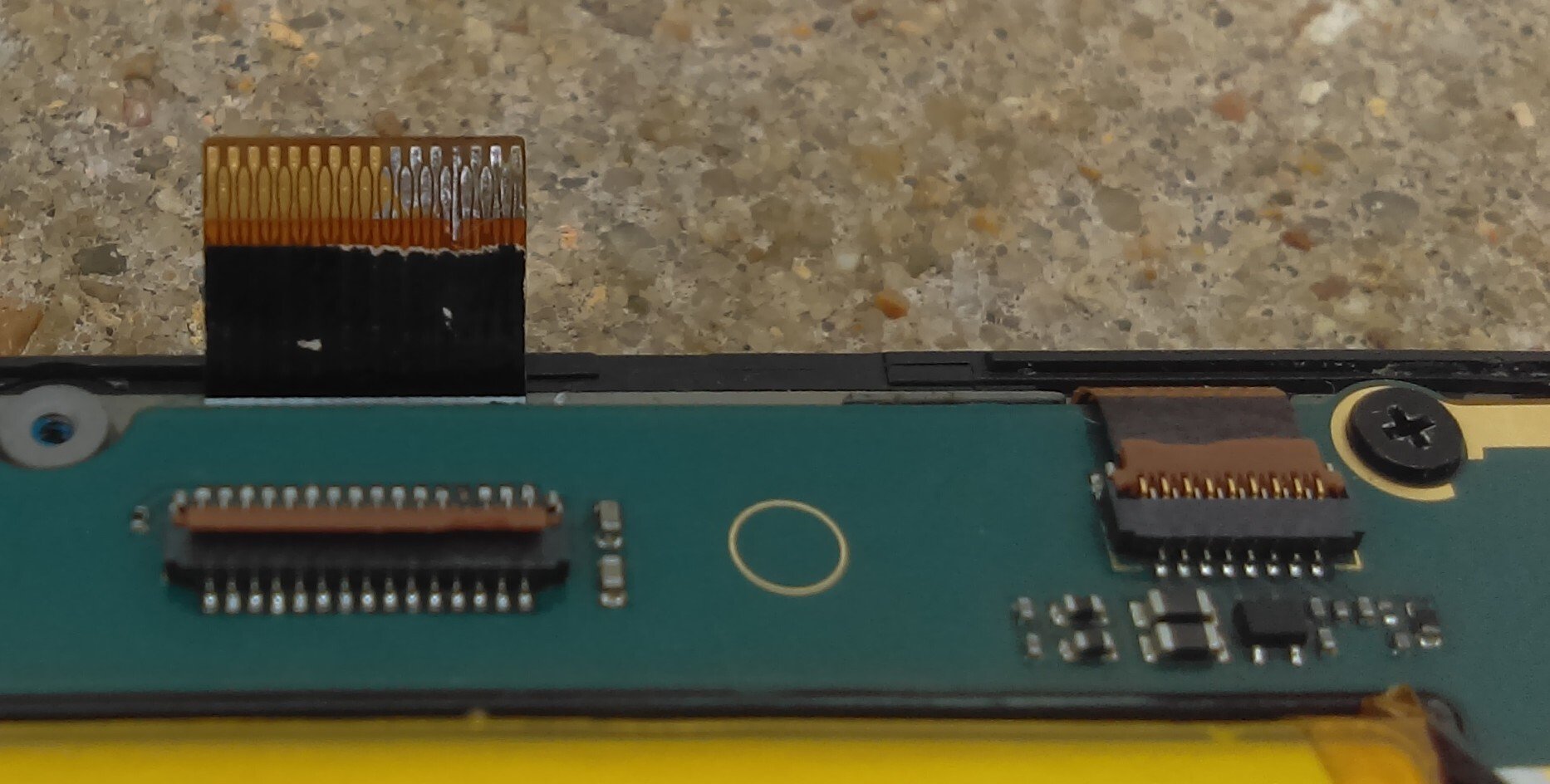

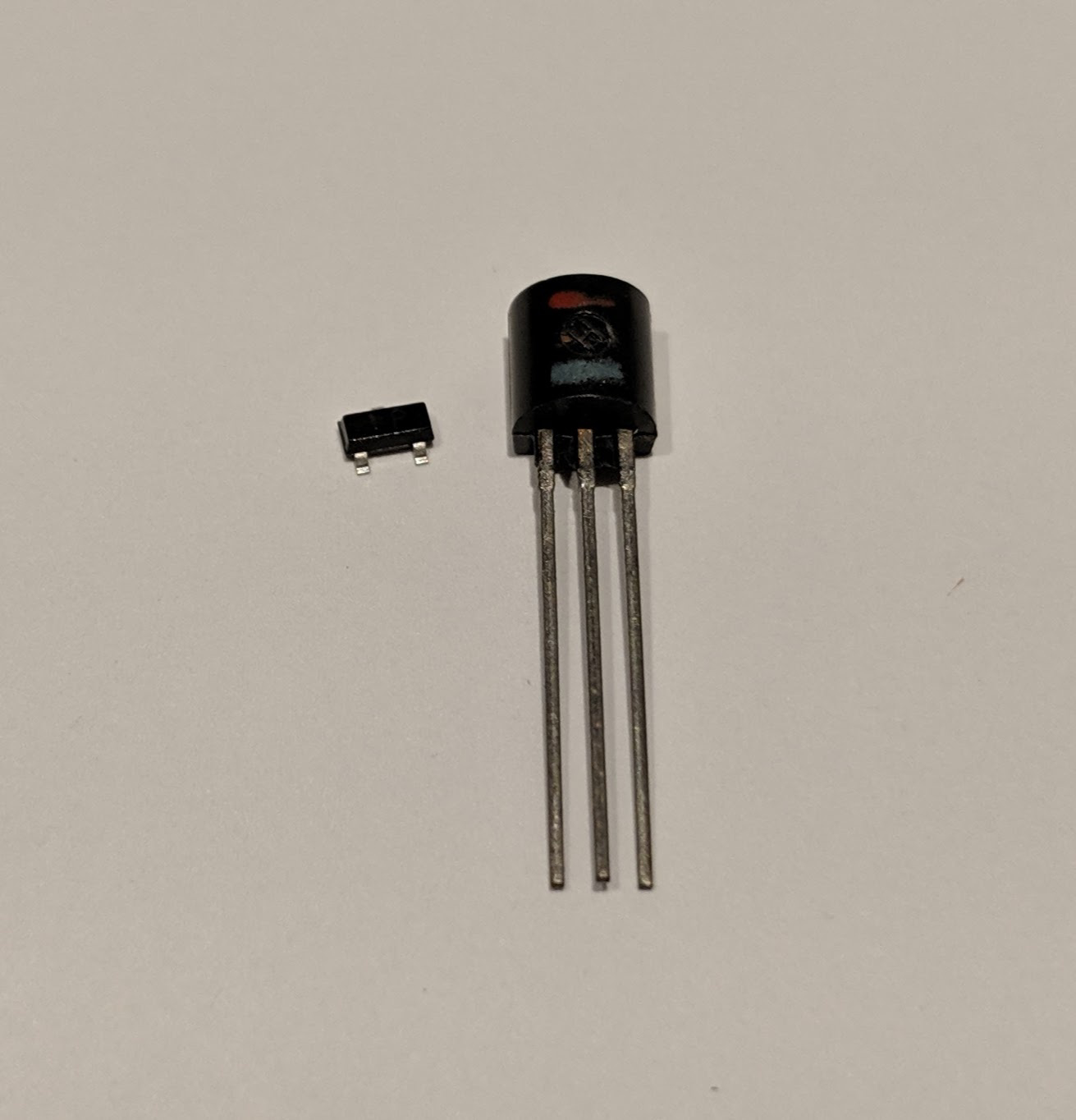

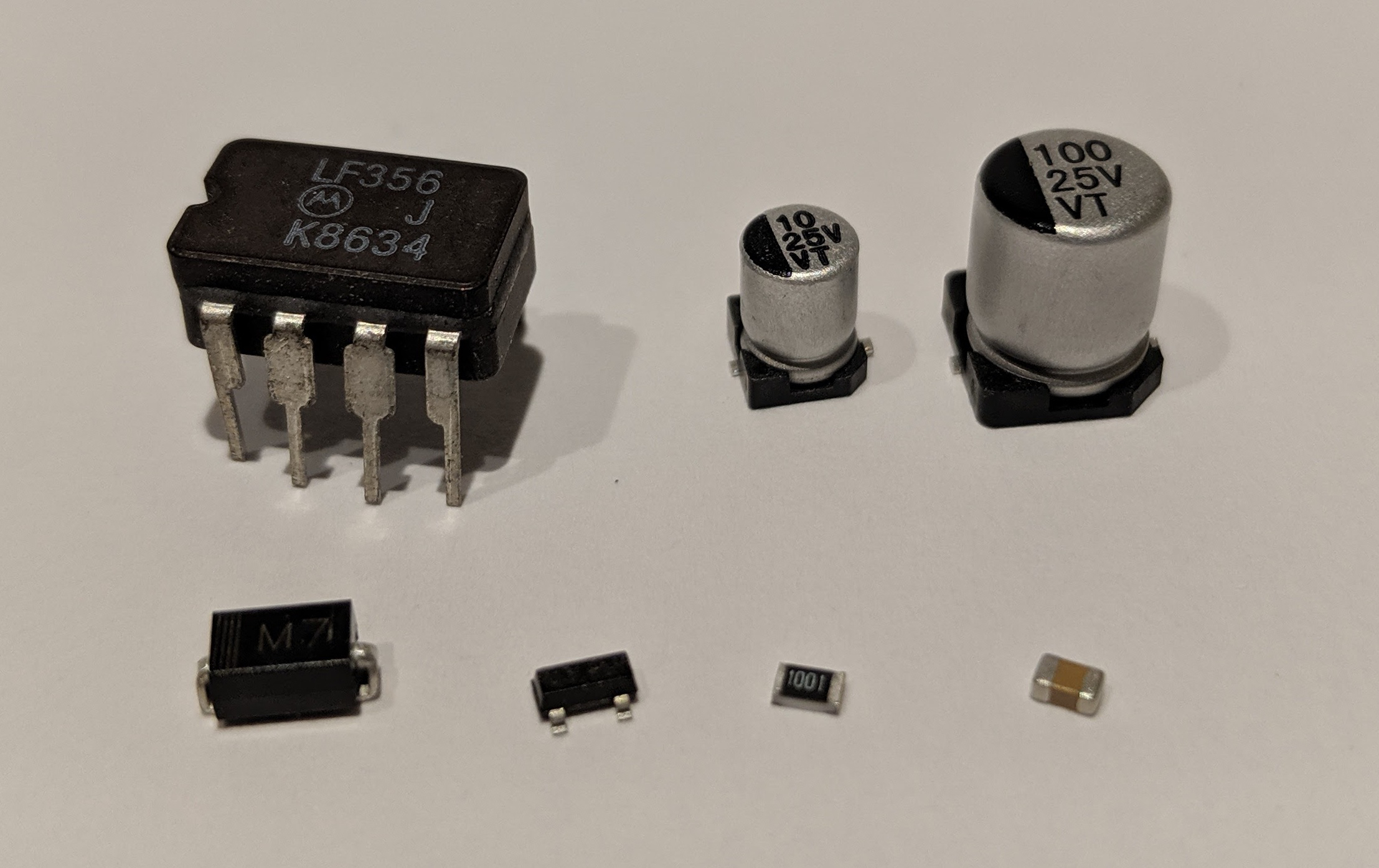

I normally have an ETA (1.6 mm chisel) tip in the PES51. It meets most of my day-to-day soldering needs. I find that I can easily solder SMDs down to 0805, SOT23s, and SOICs with the ETA.

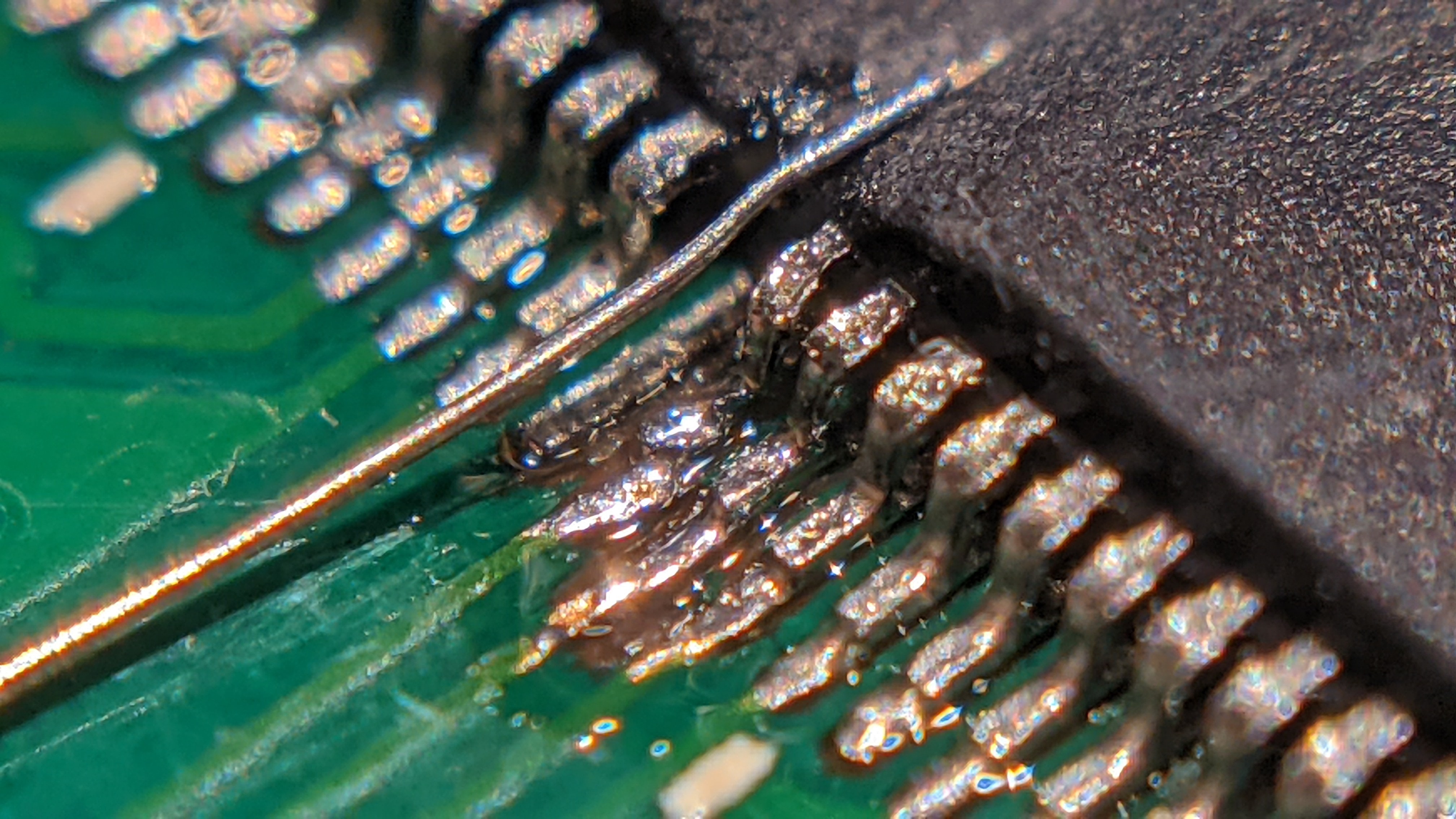

When I'm doing something like a QFP of TQFP I switch to a ETGW (2 mm beveled cup) tip. The ETGQ style Gullwing tip is the tip professionals use to hand solder chips with gullwing style pins.

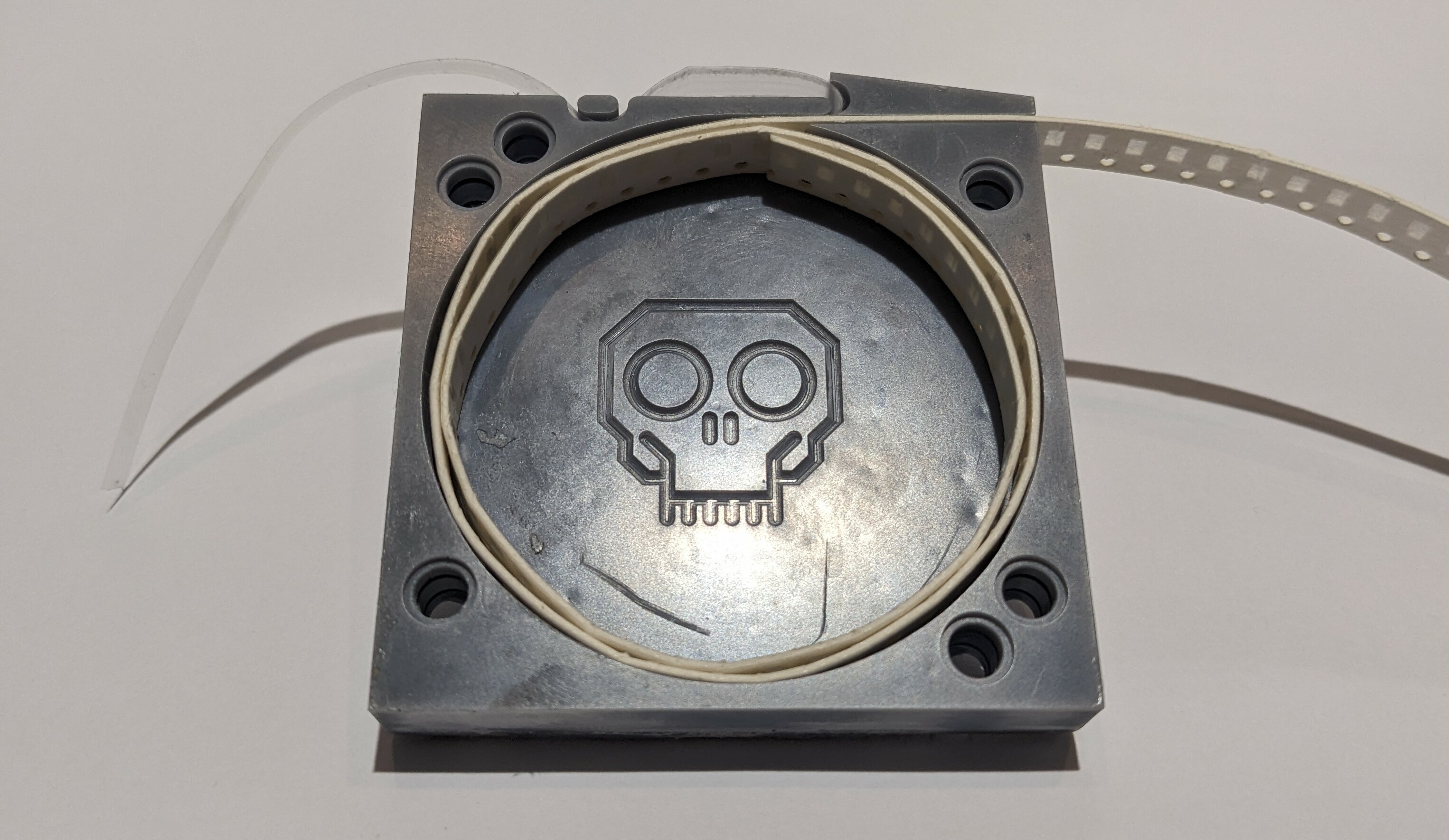

Yes, this tip is a little bit oxidized.

I cleaned out the solder to show the cup in the photo. Immediately after I took this photo I fluxed and tinned the tip. It's all good and ready for the next time I use it.

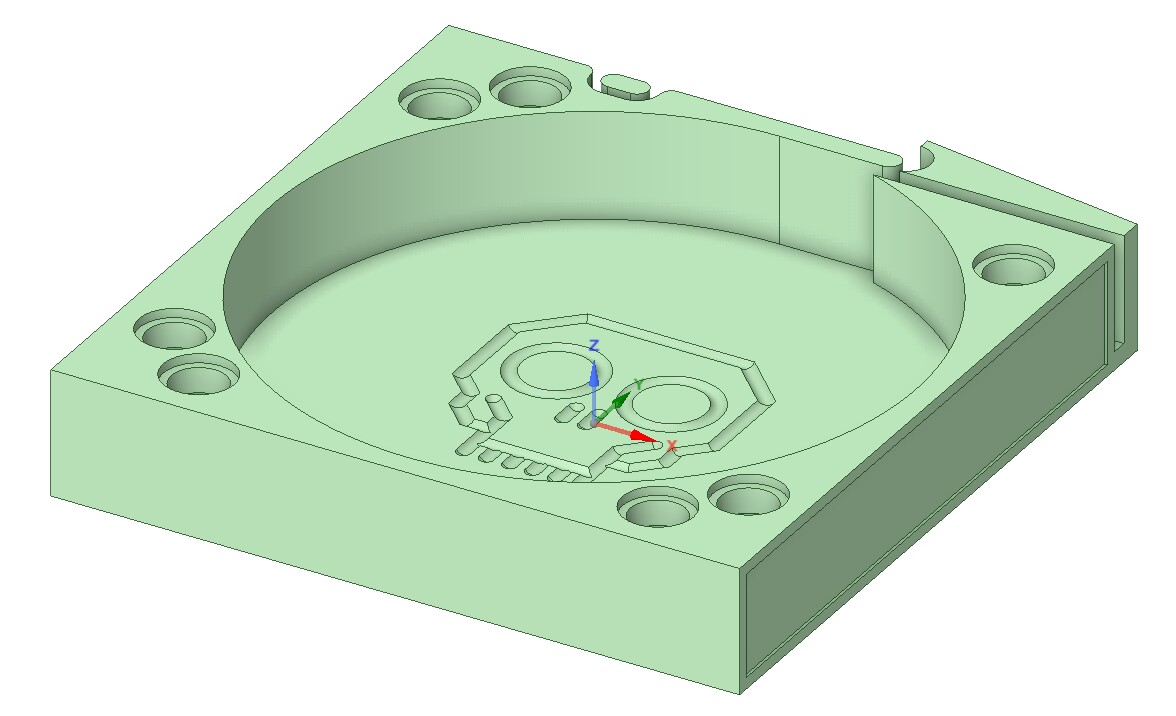

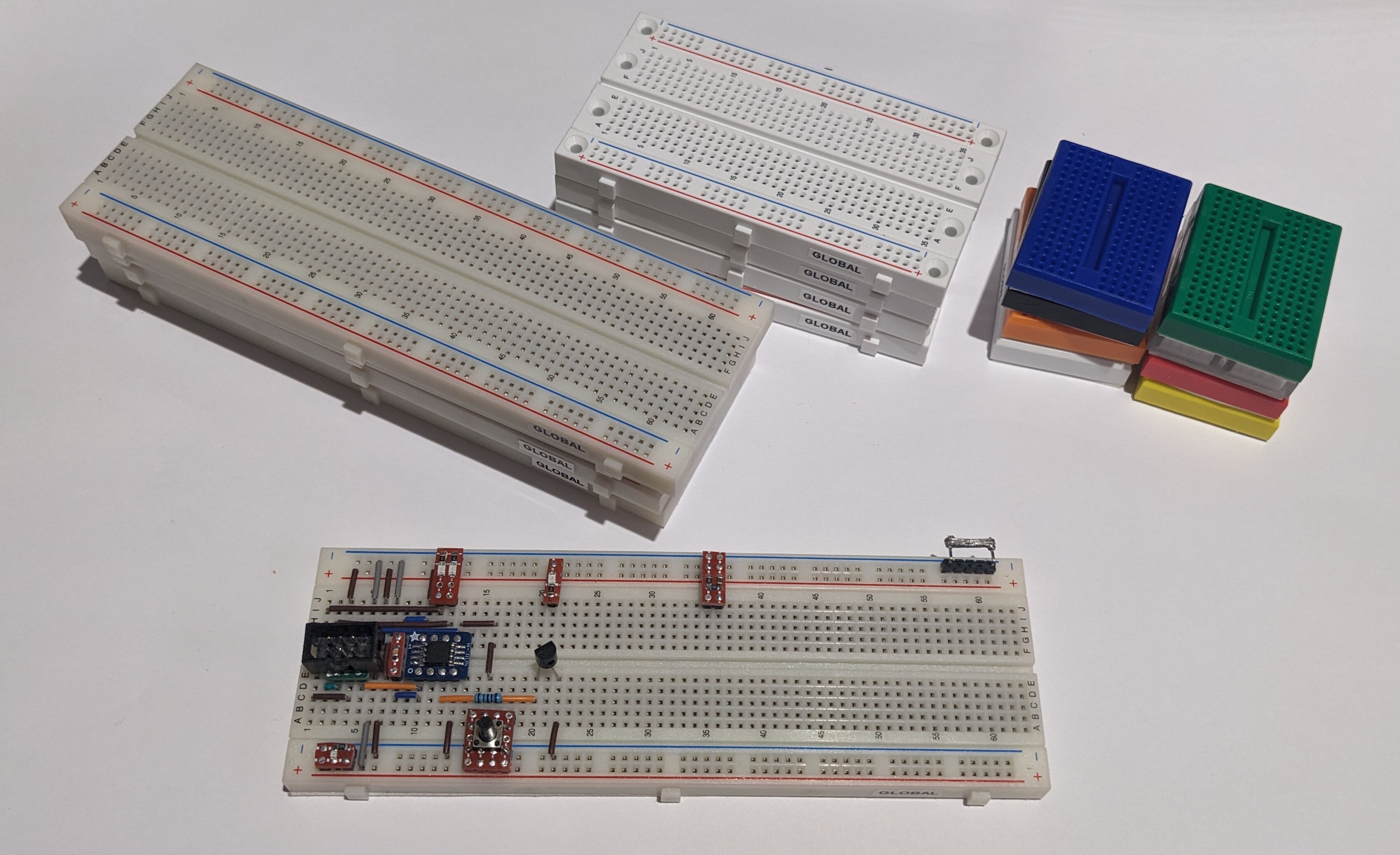

I have a range of other tips that I use from time to time when they are appropriate. They include (upper left to right then lower left to right):

ETAA - a 1.6 mm bevel

ETL - a long, heavy 2 mm chisel

ETR - a long, light 1.6 mm chisel

ETT - a 0.6 mm conical

ETU - a 0.4 mm bevel

ETX - a 0.2 mm bent conical

TETS - 0.4 mm long conical

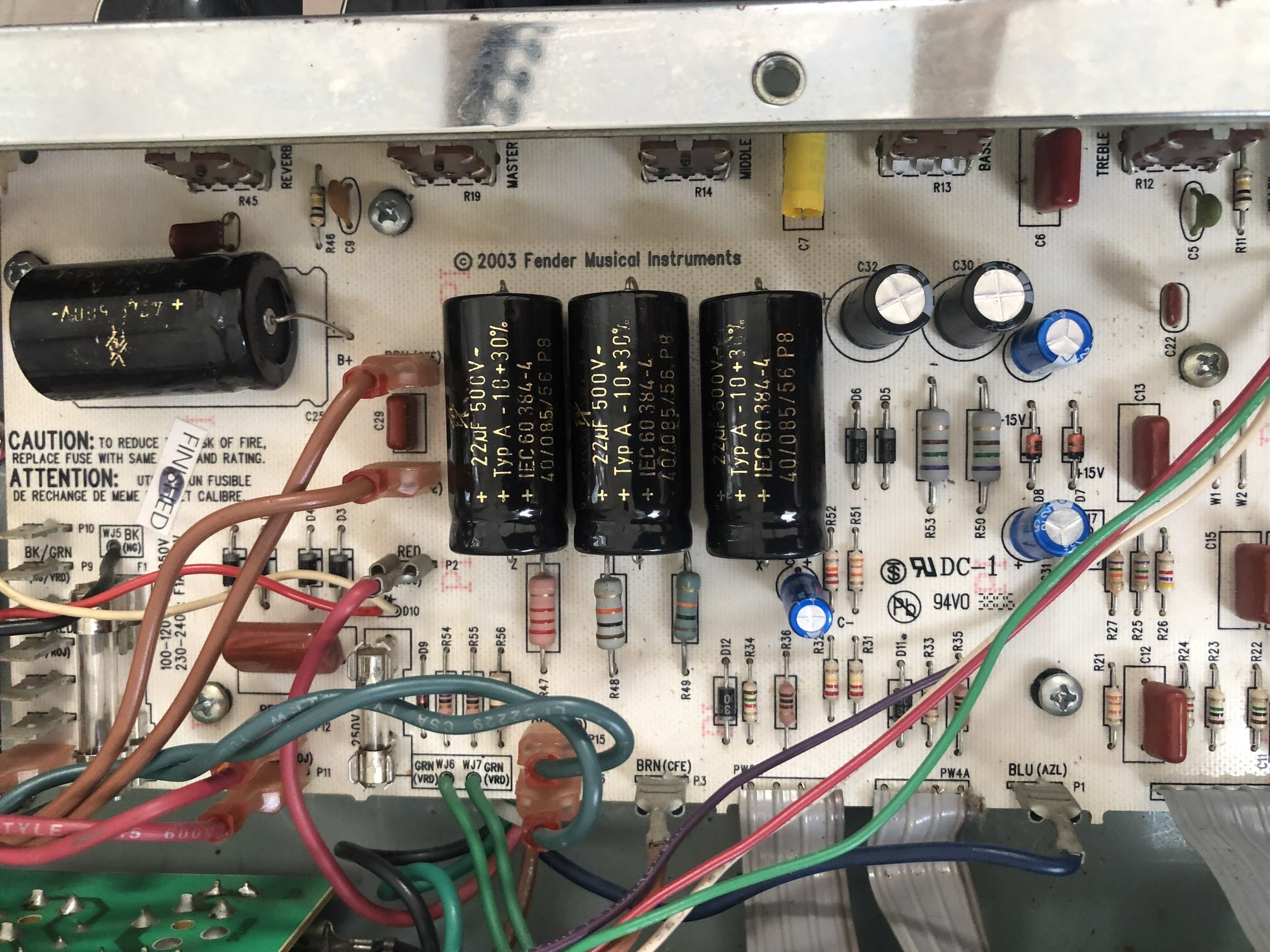

The projects that I've been taking in recently (I don't call them jobs because I often do them for free) have been more complex. I've had to desolder SMD electrolytic capacitors and I've been soldering 0.4 mm pitch TQFPs. I needed a soldering station with a bit more range.

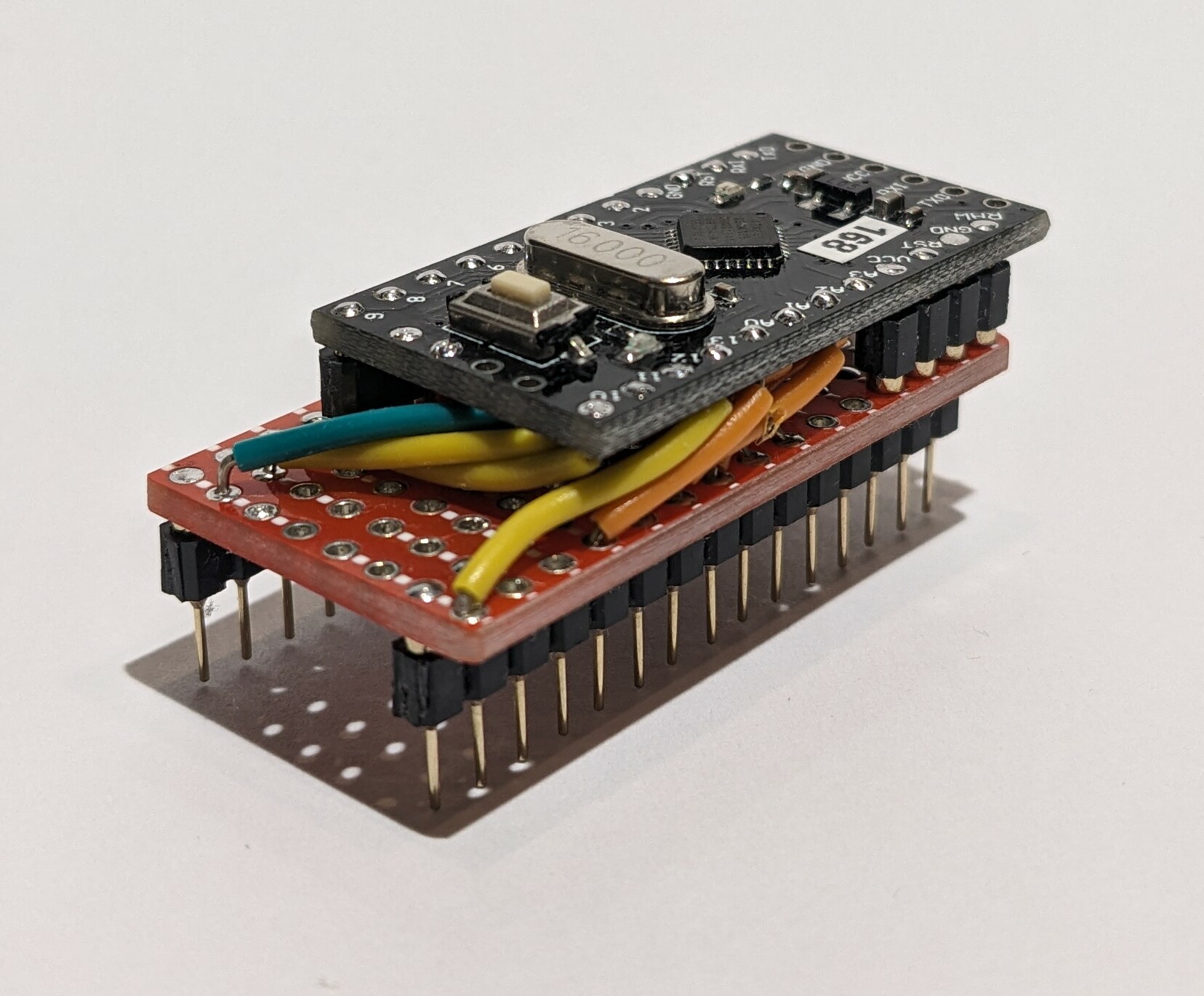

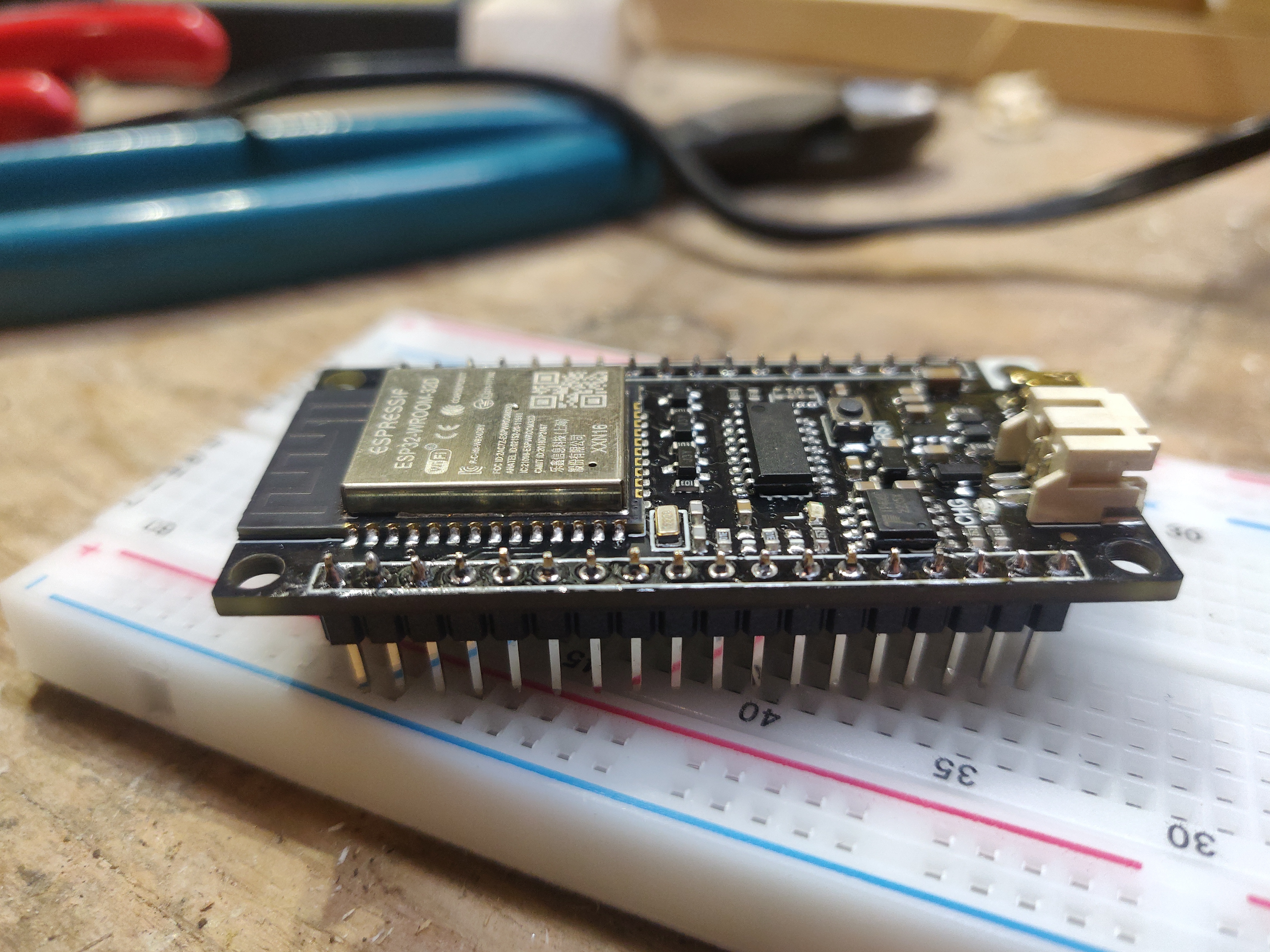

A few weeks ago my Hakko FM-203 arrived with the pair of FM-2027s you see in the cover photo. The green one is loaded with a T15-BCM2 which is a 2 mm beveled cup like the ETGW on the Weller and the yellow with a T15-D16 which is a 1.6 mm chisel like the ETA on the Weller.

I'm planning to add a FM-2022 tweezers at some point in the near future to help with those pesky SMD electrolytics.