Hey!

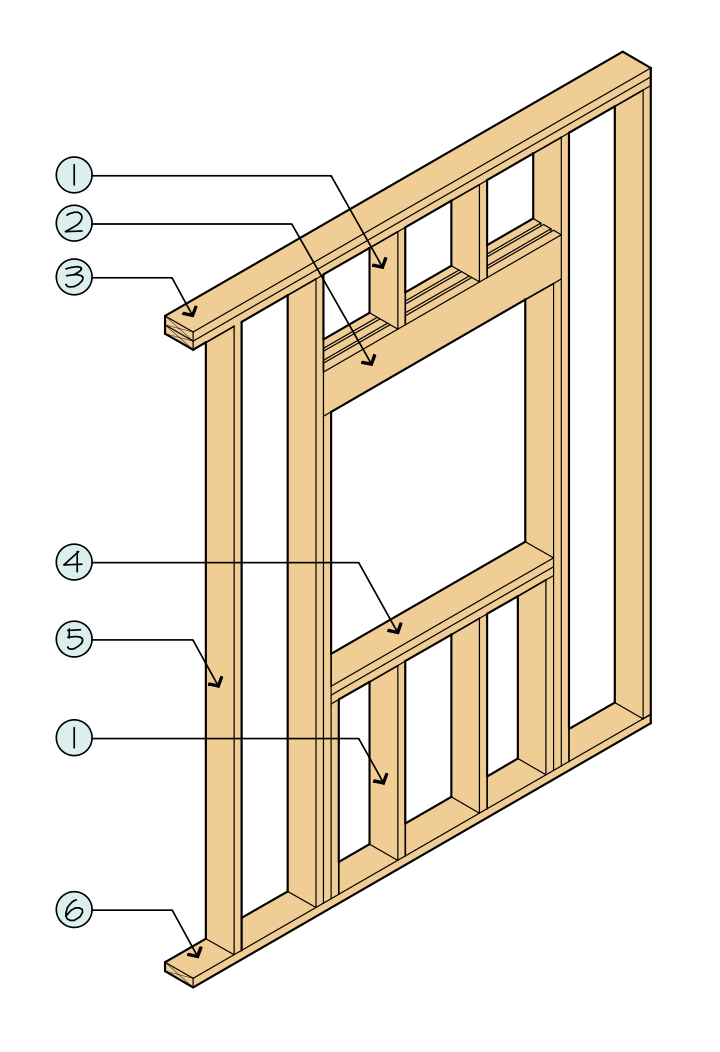

Currently doing drywall myself and I am using 6x6 cm squared timber around my outside walls.

The problem is they aren't as stable as the other walls inside the house because of the 6x6 cm squared timbers that are about 30cm distance from each other.

I will screw my plasterboards on the squared timber and only one plasterboard, not two.

I have two pictures of what my construction looks like from far and one from close.

Maybe someone can give me advice before I install the plasterboard onto it.

The only problem I currently see is finding the subconstruction once I put the plasterboards back on. But other than that, if I find them can I install the cabinets safely?