view the rest of the comments

3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: or !functionalprint@fedia.io

There are CAD communities available at: !cad@lemmy.world or !freecad@lemmy.ml

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

I assume you've been reading about other people's work on this?

https://www.diyphotography.net/3d-printing-lenses-is-now-a-thing-and-you-can-make-them-yourself/

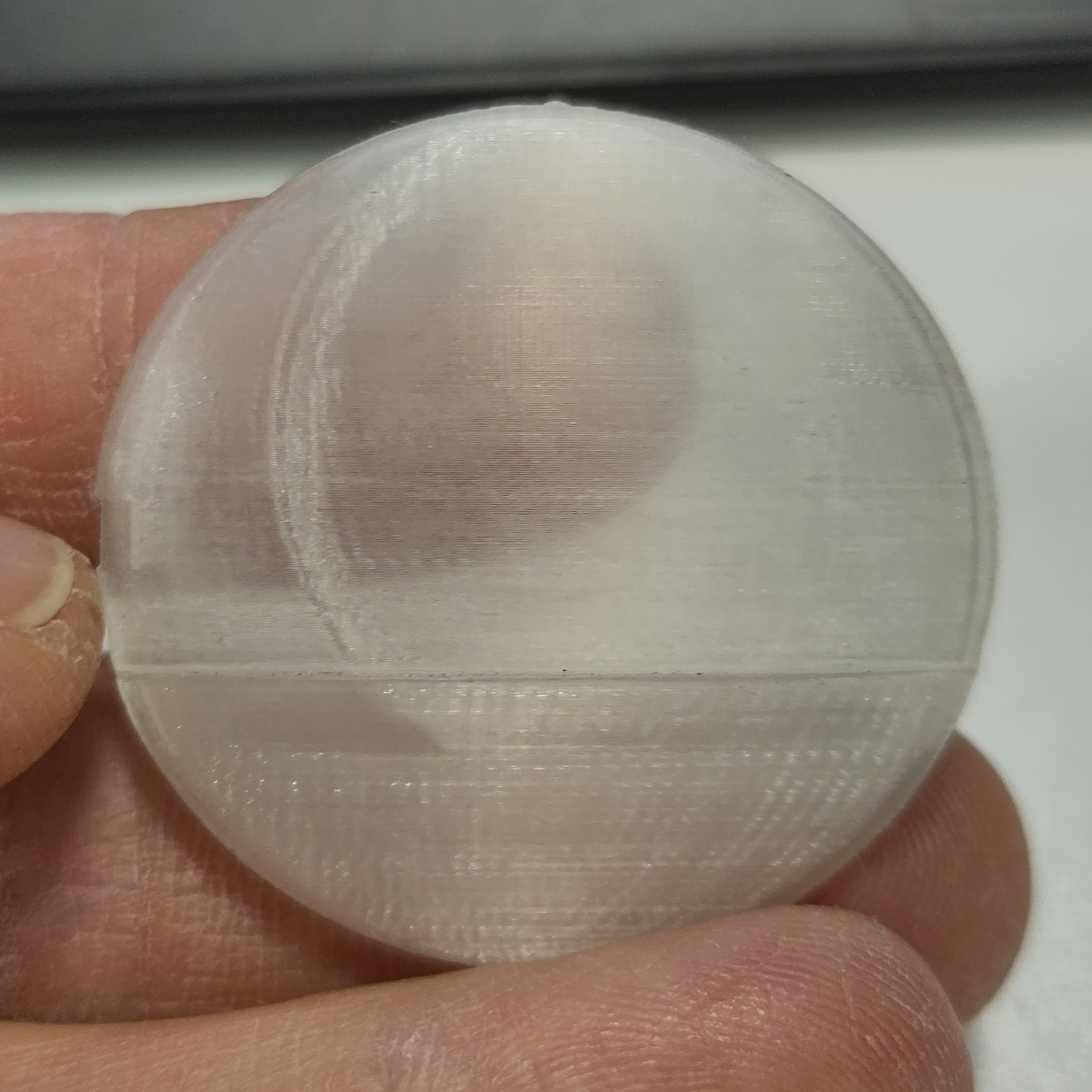

Yeah I read about others trying to make optically usable lenses. That would be great!

But my purpose was to print a dimensionally accurate template for my 3D-printed frames.

That went south because printing this object in one go with a FDM printer is almost impossible to print cleanly. So I gave up on that. But I was still curious to use it to find out if I could use acetone to reassemble two clean halves of it, and find out what kind of polish PLA can take.

You know, just out of curiosity 🙂

Might find this interesting, uses abs, there's an example at the end of using one of the fdm printed lenses with lasers

I've tried with petg, was just for looks (transparent cases) rather than optical use, wasn't super satisfied with it. Might try abs, it takes to acetone smoothing really nicely

That was a neat read, and the author managed to achieve some impressive results that I can tell you from experience will require settings that engender hella long print times.

I think it would be significantly less irritating, especially if you were going to be doing this type of thing on the regular, to print molds of the negative of your object with your FDM printer and then cast the final product in resin which will be inherently solid and (theoretically, done correctly) consistent and without the possibility of internal voids.

I mean, if you're going to be hand-polishing the shit out of everything at the end of it anyway...

That's pretty fun. Good luck!