Opposing and complimentary, like the yin and yang; dichotomous, a contrast between light and dark.

That doesn't remind you of anything topical, does it?

This is the Craighill Sidewinder, and it's got it all in twos. Two handle halves, obviously, in two different finishes. It even has two designers, Kai Williams and Chen Chen, who describe it as "an enigmatic kinetic sculpture moonlighting as a knife."

And its mechanism is, yes, weird.

The handle is comprised of four steel plates forming two halves each, sine-wave shaped and with one stonewashed and the other black PVD coated. It has two pairs of pivots, and when you swing the blade open the handle halves swap places with each other.

If you compare the open and closed pictures you can spot the difference. It's hard to explain in writing. Here, watch this:

The action really is sublime. It's an art exhibition in motion.

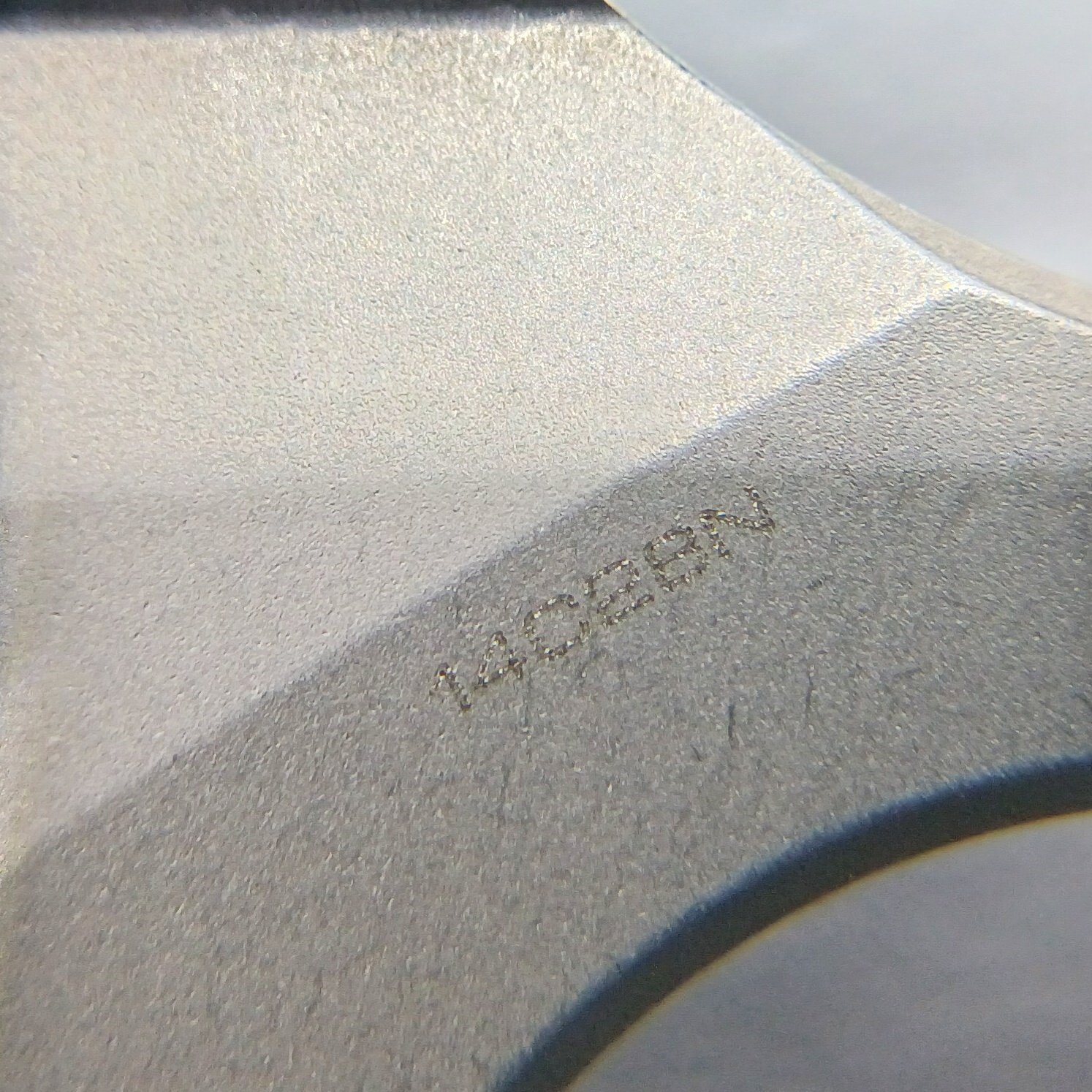

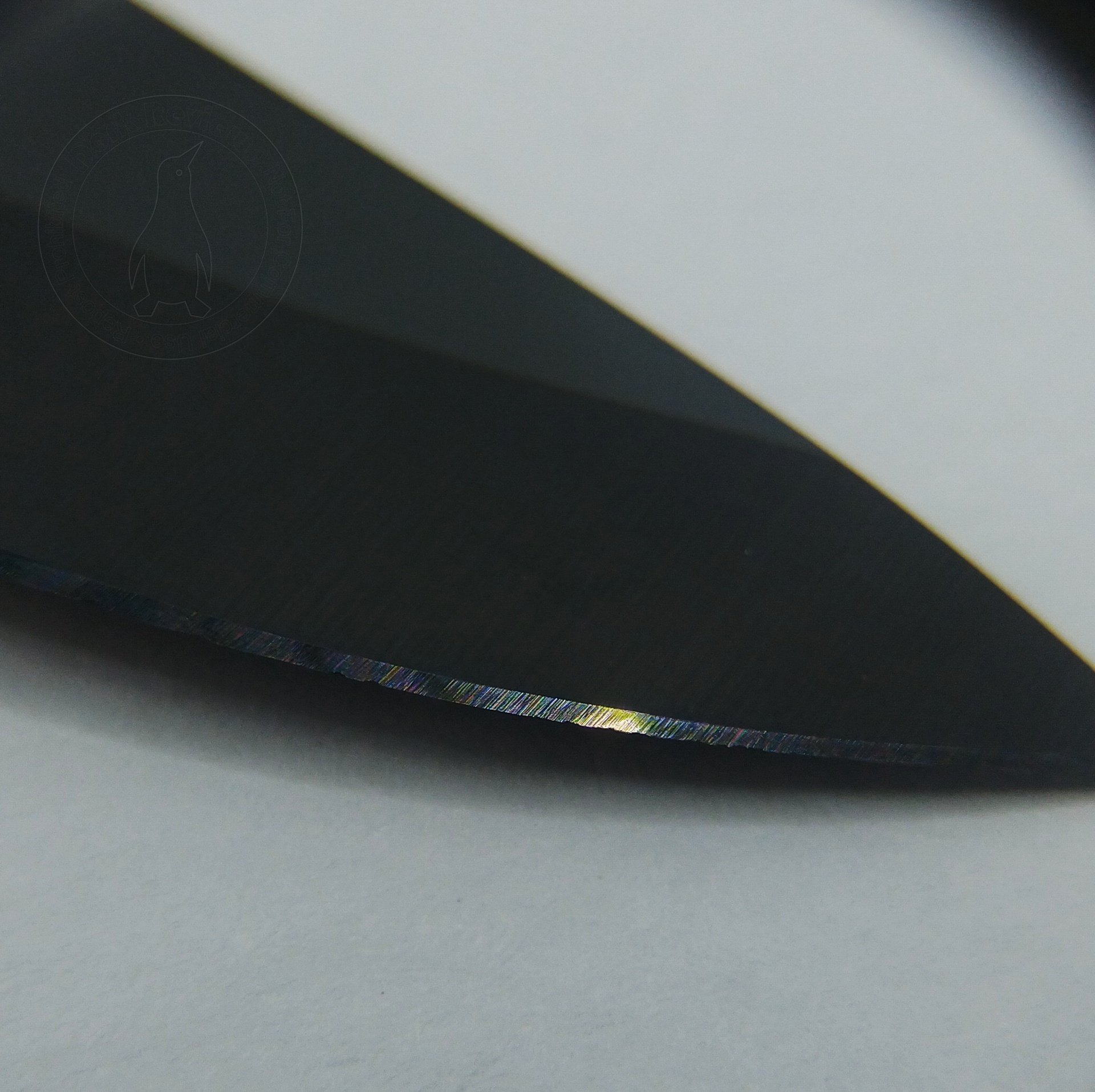

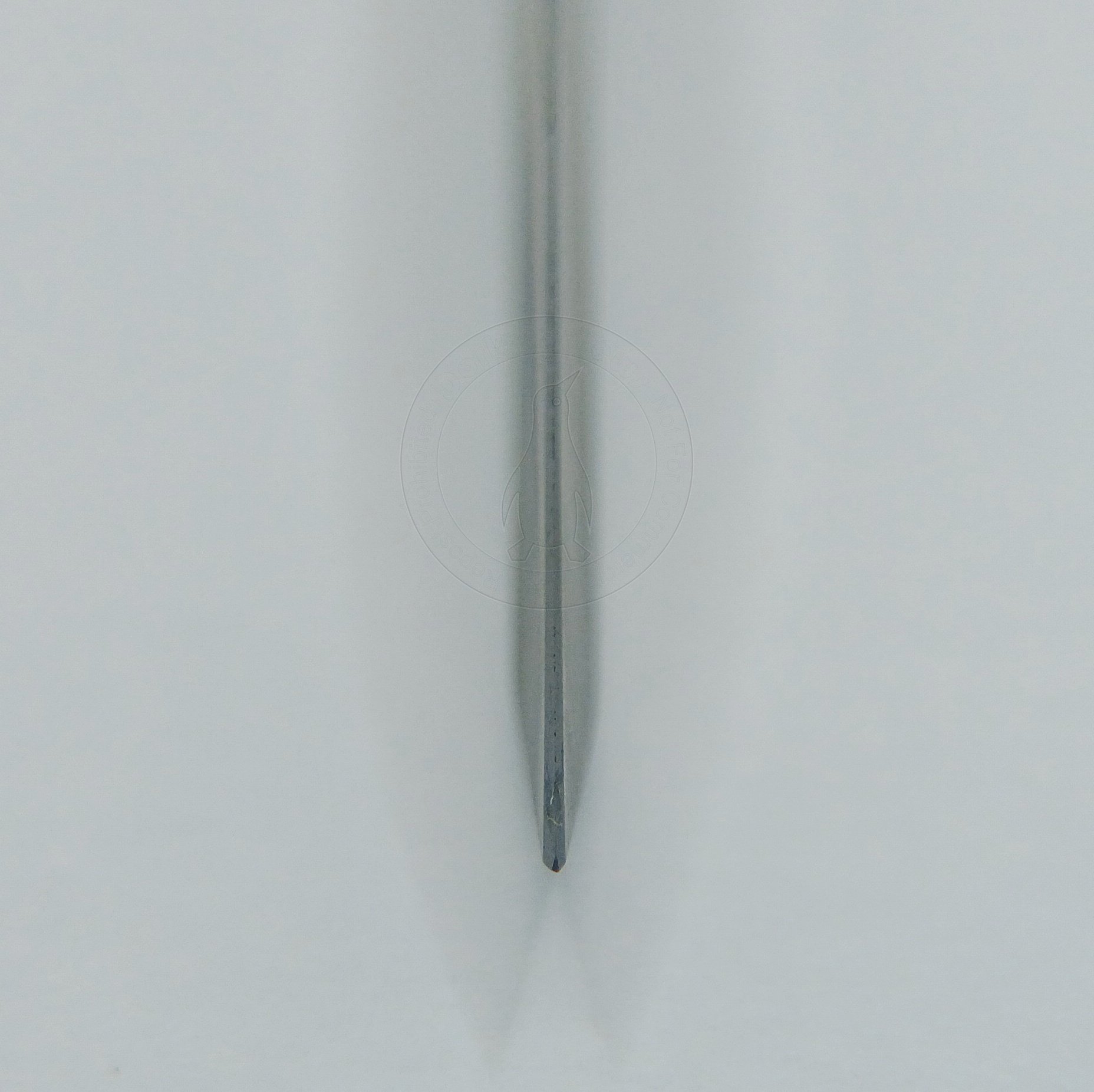

The Sidewinder is compact, but being made entirely of steel it's extremely heavy for its size. 160.3 grams or 5.65 ounces, despite being only 4" long when closed. It's got a 2-5/8" long blade made of 12C27N, which is certainly a very capable if admittedly not very fancy steel.

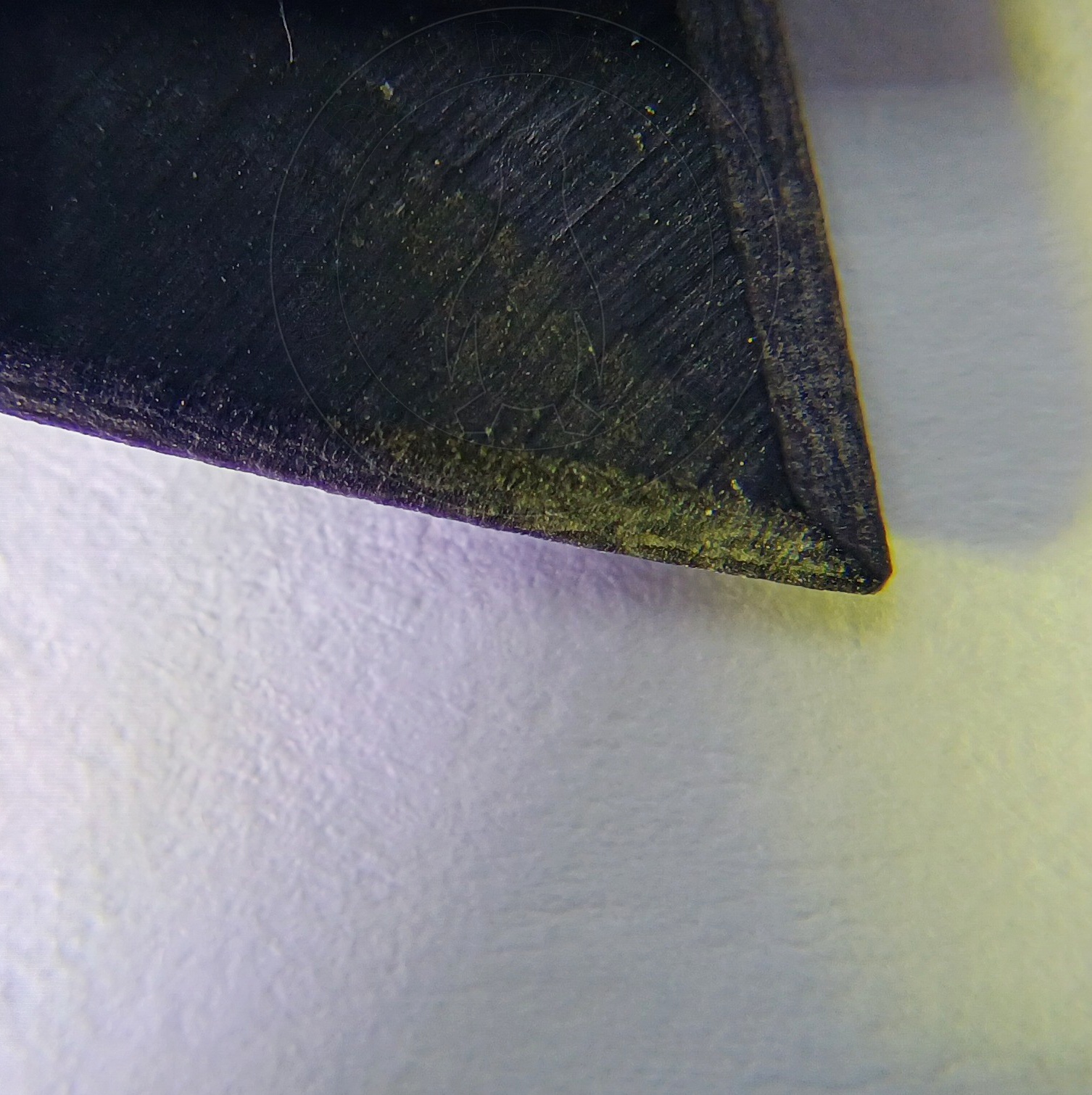

But that, too, is nicely stonewashed. It has a drop pointed blade that, in keeping with its entire symmetry jam, has the point precisely centered along its width.

It's a liner locker although if you ask me, having a lock at all is probably unnecessary since this is one of those mechanisms where your grip on the handle inherently clamps the blade into position. The detent ball that keeps it from flopping open in your pocket is on the liner, though, so removing it isn't really advisable.

And sloshing around loose in your pocket it will be, because the Sidewinder does not have a clip nor does it have a lanyard hole or any other carrying provision. It doesn't even some with a perfunctory cheap ballistic nylon belt pouch. No, if you're going to carry this you have to suffer for your art and be prepared for commitment.

There isn't a thumb stud, either. This is a flipper opener.

To assist with this it has ball bearing pivots -- ceramic ones, no less -- the carriers for which you can see in the handle gaps.

With a bit of finesse it does indeed flick open very easily. You have to remember to hold it only by the black part, though, because the silver part will swing forward along with the blade and if you're holding onto that it'll stop short. This means you probably have less of a grip on it than you'd like and I certainly wouldn't want to try to bust this out in a hurry under duress. It's a fine line between an elegant draw to the adoration of all onlookers versus sinking the thing juddering half an inch into the floorboards.

I think the Sidewinder's mechanism is extremely clever, so obviously I took it apart for you.

There's actually not as much in there as you'd think, but there are no less than eight ceramic ball bearing assemblies owing to the thing technically having four pivot points.

The hardware consists of said pile o' bearings, eight screws, and a quartet of threaded barrels with anti-rotation flats in them. Theoretically you should be able to remove either screw from either end to get the pivots out, but I found that one side of mine was permanently threadlockered and the other side wasn't, effectively converting these into normal male/female screws.

On the tail end is a little curved plate like the barrel link of an 1911, with two holes in it that actuates the pair of pivots opposite the main one when you swivel it open. The curve is in it for a reason, and it's shaped just so that it never actually protrudes from the handle at any time or in any position throughout the action's travel.

The mechanism is actually extremely simple, and its elegance comes down to just how precisely the machined halves of the handles slot together in both the open and closed positions. I've outlined it for you thusly:

Because both the open and closed states wind up with the halves interlocking so thoroughly, there is no need for endstop pins and the blade absolutely cannot overtravel, nor strike the toggle on the end even though it looks like it ought to be able to. The lockup is very solid and there's no lash in the blade in any direction when in the open position.

It's also worth mentioning that while it appears the scales could all be duplicates of each other, they're not. Each and every one is slightly different from the others, with one of the silver ones having the cutout for the liner lock in it which is a separate leaf that's screwed into place, while only one pair have the D shaped anti-rotation holes in them while the other two just have round holes.

At the end of the day it doesn't really make any difference which way you insert which screw, although half of them are silver and half of them are black, and you probably won't want to mix them up.

The Inevitable Conclusion

The Sidewinder is a tad on the expensive side but there's no denying it's extremely well built and it's got style out the ying-yang. There isn't a single whiff of mall ninja about it. It's pleasingly refined, elegant, grown up. Very gentlemanly. The machine work is impeccable, with every edge smoothly chamfered and every surface fully finished, even the inside faces where you'll never see or touch.

Maybe it's small, and maybe it's not made out of the latest trendy supersteel, but when you're holding it you don't care. It's not your partner's clothes or makeup or perfume that matter. The beauty is in the dance.

He is not a sitting president yet.

He was not a sitting president when the offenses occurred in 2016, either, when he had yet to be elected. Even if the "presidential immunity" ruling could somehow be twisted to apply to this as if it were an official act, he was in no way shape or form president at that time.