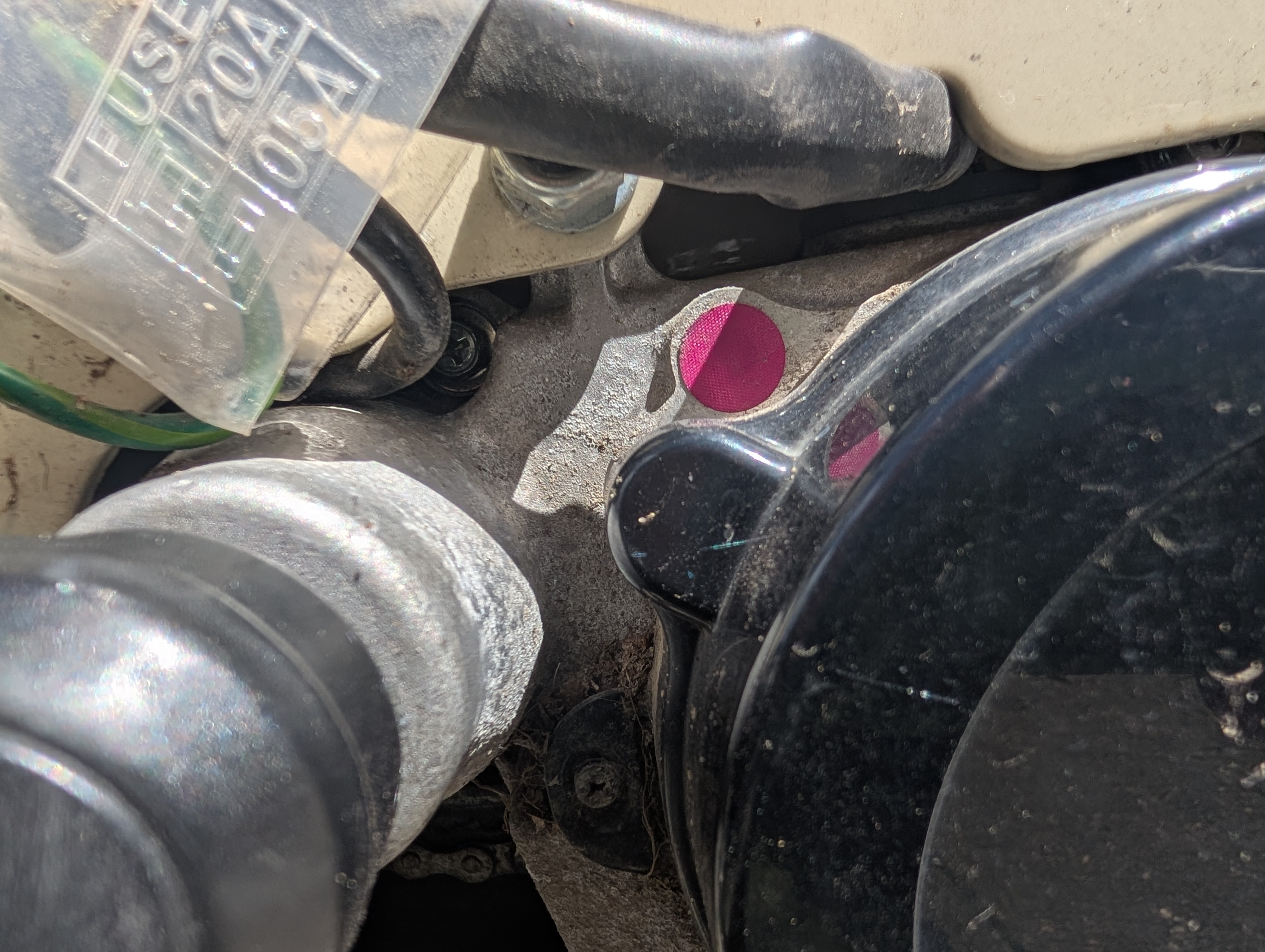

I've put off the overhaul of my ebike's Bafang G510 mid-drive motor for so long that it has never actually been serviced since I bought it 3800 km ago. Over the past weeks, I slowly pulled the motor off the bike, carefully disassembled it, and found the rotor shaft gear in a poor state. Metal flecks were visible within the blackened grease, making a mess within the housing.

To get the sprockets off of the motor, I did have to obtain a deep-socket YC-29BB tool to remove the "spider" from the crank shaft. A standard wrench for the Bafang lock ring will not work, because the spider itself is in the way.

This motor has an all-metal gear arrangement, consisting of the primary gear axle which is coaxial with the cranks, a secondary gear axle, and a tertiary gear axle which is driven by the rotor shaft gear. It was the gears where the tertiary axle and rotor shafts meet which were substantially ground down, resulting in play between gears that causes additional wear every time the motor accelerates or decelerates.

Note: some references online say that the G510 pre-2023 had a nylon gear. I could not locate any images of this, and my motor appeared to have all-metal parts. So idk.

Part of the issue is that the tertiary axle used a gear which isn't as deep as the rotor shaft's gear, resulting in wasted gear-to-gear surface area. A newer gear design for both the rotor and tertiary axle came out in 2023, and can be swapped in but requires recalibration of the motor.

So with the motor half disassembled, I figured the only sensible way forward was to order both the new rotor shaft and new tertiary axle, plus the CAN bus-specific Bafang dealer tool to perform the recalibration. I purchased these from greenbikekit.com, which didn't have the most intuitive ordering process but they did deliver in the end.

Perhaps the most arduous process was cleaning out all the old grease, which requires some solvent to shift. And even then, some crevices were unreachable without a very long cotton swab. In any case, I then re-greased using Permatex 80345 white lithium grease, since this has a higher temperature rating than typical white lithium grease, according to its data sheet. I obtained this from the local auto parts store, and this was the best I could get locally; Mobilgrease 28 was not available near me.

For the recalibration procedure, I knew that I wouldn't have -- nor would want to register for -- the Bafang dealer software to use with the programmer tool. Also, I'm a believer in the right-to-repair and having to beg for software is antithetical to this notion. Fortunately, someone has a FOSS project that can control the programmer and issue the recalibration command, among other neat features.

After dealing with a file permissions issue for /dev/usbhid2, the programmer was able to issue the calibration and the motor was set for reinstallation into the frame. This was basically all the earlier steps in reverse.

During testing, it is notable how much the new gears add the characteristic "whirling" sound of an electric motor. However, because the play within the gears was reduced and with new grease added, I found that the overall noise signature of the motor is substantially reduced. Also appreciated is how much less current the motor draws when riding at speed, compared to before the overhaul.

While it did take a while to assemble the parts and procedure for this endeavor, I am pleased with the results and would suggest periodic re-greasing for ebikes in regular service.